- Home

- About Us

About Us

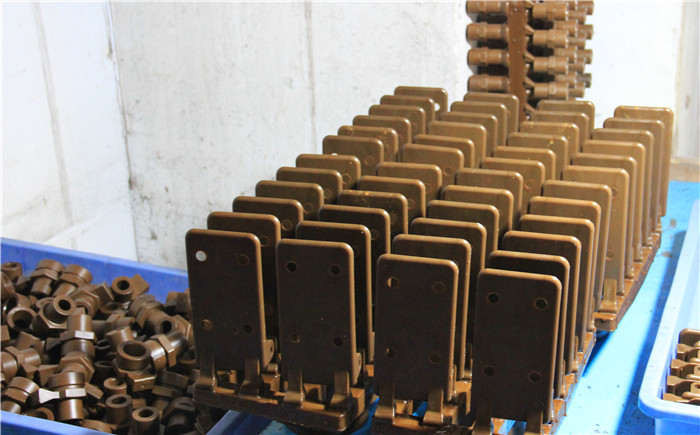

Qingdao FSK Foundry Materials Co.,Ltd Who has been serving to the needs of foundry materials since 2000. Our Core Values is “ Specialty Service Casting, integrity Casting the Future ”.

We specialize mainly in the Pattern Wax,Silica Sol(Colloidal Silica ),Mullite Sand/Powder(Chamotte Sand/Powder), Quartz Sand and Flour(Natural and Fused ) , Zircon Sand and Flour,Slag Remover,Paraffin Wax and other foundry materials .

- Product Center

Product Center

Pattern Wax,Colloidal Silica,Fused Silica Sand,Slag Remover and other foundry materials.

- Marketing Center

- Contact Us